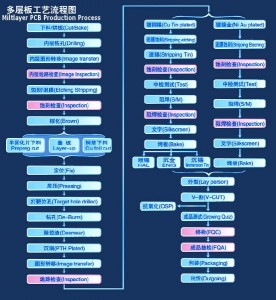

Today we have a look at the aluminum PCB production process. Please see below details.

First, Cut matetial;

Second, drilling holes

Third, the dry / wet developing

1, Dry / wet film developing process: nogplate – film – exposure – developing

Fourth, the acid / alkaline etching

1, Acid / alkaline etching process: etching – Stripping – dry – check board

Fifth, silkscreen soldermask and characters.

Sixth, V-CUT outline;

Seventh, testing, OSP;

Final, FQC, FQA, packaging, shipping.

The aluminum PCB production process is almost the same as other rigid pcb. CMD Cirsuits have a very strict qualtiy control system for the aluminum pcb and flexible pcb products, we pride ourselves on our quality and this is our selling point. Please contact us for any inquiry.