This time let’s to know the performances of flexible circuits.

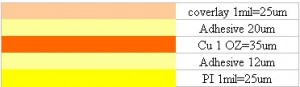

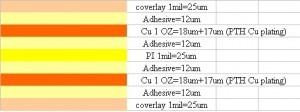

(1) Base material:

PI(Polyimide) is the most common used, which is a kind of macromolecule material of high temperature proof and high strength, invented by Dupont. The polyimide made by Dupont is called Kapton. Besides some polyimide made in Japan can also be found. Its price is much lower. Polyimide can bear 10 seconds of high temperature of 400 degree centigrade. Its tensile strength is 15,000~30,000 PSI. The base material with 25um thickness is the cheapest and the most popular one. If we need the circuit board to be more rigid, we should choose 50um. Otherwise, if we need the circuit boards to be more flexible, then choose 13um.

(2) Adhesive:

It is divided into epoxy resin and polyethylene, they are all thermosetting adhesive. The polyethylene’s strength is lower. If we hope the circuit boards to be more flexible, then choose polyethylene. The thicker the base material and the adhesiveon it is , the more rigid the circuit boards are. If the circuit boards have to be bent in a large area, we should choose thinner base material and adhesive so as to reduce the stress on the surface of the copper, then lower appearance of micro crack.

(3) Copper:

It is divided into rolled annealed copper foil and electrodeposited cooper foil. Rolled annealed copper foil is of high strength and can stand bending, but its price is higher. Electrodeposited copper foil is much cheaper, but of low strength, easier to be bent.

When we choose to use rolled annealed copper foil, we should pay attention to the direction of the copper. The direction of the copper has to be the same with the bending direction of the circuit boards.

(4) Coverlay with adhesive:

25um coverlay would make the circuit board more rigid, but it is cheaper. Therefore to the circuit board needing to be bent greatly, we’d better choose 13um coverlay.

The adhesive is also divided into epoxy resin and polyethylene. The FPC using epoxy is more rigid. After thermosetting, there are some adhesive squeezed out at the edge of the coverlay. If the soldering pads are larger than the hole on the coverlay, the adhesive squeeze out would reduce the size of the soldering pads and lead to irregular edge. Therefore, we’d better choose 13um adhesive.

These are more details about the performances of the flexible circuits. If you still need more information, please do fell to contact us.